The Project

Application of intelligent techniques in the grinding process. Aplicación de técnicas inteligentes en el proceso de rectificado (S-PE11UN109)

- Lead Researchers: Eva Portillo Pérez - (01/01/2011 - 31/12/2012)

- Research Area: Intelligent manufacturing and industry

- Funding Body: Basque Country Government, Department of Industry, I

Objectives

As part of the grinding process, the aim of this project is to implement a hybrid model in which the artificial neural networks are a necessary complement to the analytic models. In particular, this approach allows for obtaining parameters of the models that are closer to reality and that allow for, as well as improved knowledge of the process, better simulation of its behaviour with the waiting time of the machine. transfer rumours

Thus, we propose the design of an intelligent system capable of estimating the tool wear (wheel) and the rugosity of the part without stopping the machine to make those measurements manually, which could increase the performance of the griding operations.

Achievements

Amongst the achievements of the project, we can highlight the following:

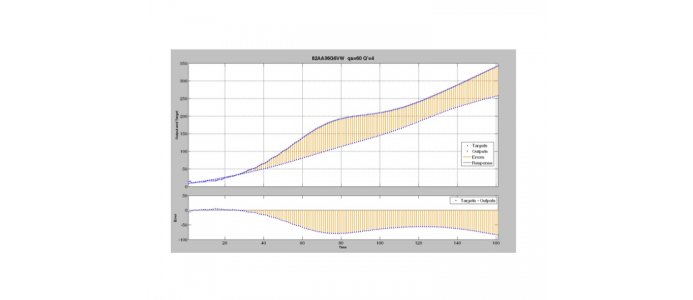

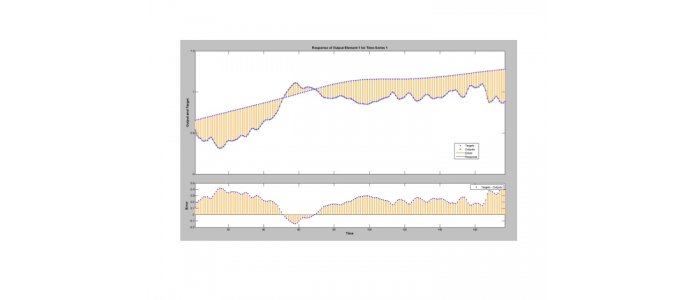

- Configuration of an artificial Neural Network in the recurrent architecture Layer (derived from Elman) to predict the rugosity of both new wheels and those used during training under different cutting conditions..

- Configuración de Red Neuronal Artificial basada en la arquitectura recurrente Layer Recurrent (derivada de Elman), para predicción del desgaste tanto en muelas consideradas durante el entrenamiento bajo distintas condiciones de corte, como en muelas nuevas.

Acknowledgements

This work has been funded by the Department of Industry, Innovation, Commerce and Tourism within the framework of the Saiotek Project (S-PE11UN109): Application of intelligent techniques in the grinding process.

Software

In order to carry out the example preparation, training and validation phases, we developed different applications using the neural network tool MatLabTM, DataNormalization, DataPrepare, NewDesign and NetSim.