Analysis of power in the drilling process to move towards new control strategies. Análisis de la Potencia en el Proceso de Taladrado para el Planteamiento de Nuevas Estrategias de Control (PT10048)

- Lead Researchers: Eva Portillo Pérez - (18/10/2010 - 18/12/2010)

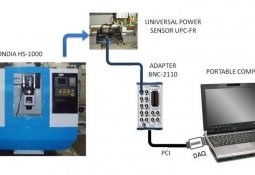

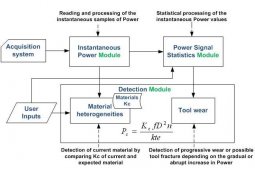

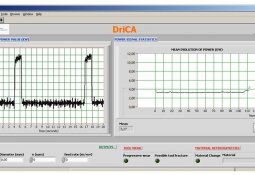

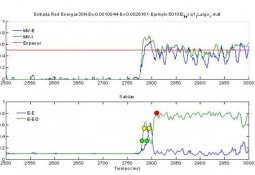

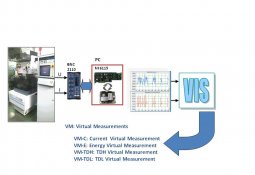

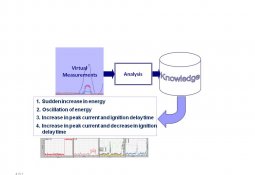

The aim of this work is to analyse drilling process behaviour to evaluate the possibilities of designing a control system that allows us to increase productivity and to efficiently manage tools with a power supervision loop. In order to carry out this analysis we first propose a testing methodology to extract maximum knowledge about the process. This trial methodology involves trials in both a stable regime and degraded regimes caused by the wear or breakage of the tool. Second, it is necessary to define and...

Read more