Application of intelligent techniques in the grinding process. Aplicación de técnicas inteligentes en el proceso de rectificado (S-PE11UN109)

- Lead researchers: Eva Portillo Pérez - (01/01/2011 - 31/12/2012)

- Funding body: Basque Country Government, Department of Industry, I

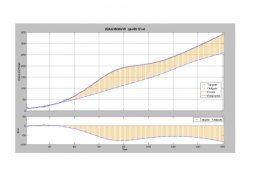

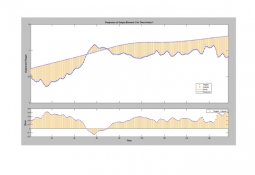

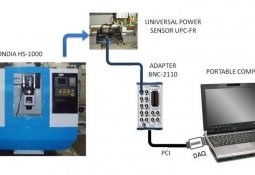

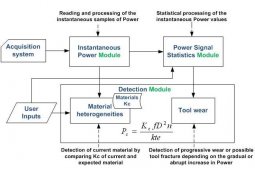

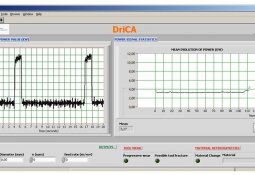

As part of the grinding process, the aim of this project is to implement a hybrid model in which the artificial neural networks are a necessary complement to the analytic models. In particular, this approach allows for obtaining parameters of the models that are closer to reality and that allow for, as well as improved knowledge of the process, better simulation of its behaviour with the waiting time of the machine. transfer rumours Thus, we propose the design of an intelligent system capable of estimating the...

Read more