The Project

Analysis of power in the drilling process to move towards new control strategies. Análisis de la Potencia en el Proceso de Taladrado para el Planteamiento de Nuevas Estrategias de Control (PT10048)

- Lead Researchers: Eva Portillo Pérez - (18/10/2010 - 18/12/2010)

- Research Area: Intelligent manufacturing and industry

- Funding Body: IDEKO, S. COOP.

Objectives

The aim of this work is to analyse drilling process behaviour to evaluate the possibilities of designing a control system that allows us to increase productivity and to efficiently manage tools with a power supervision loop.

In order to carry out this analysis we first propose a testing methodology to extract maximum knowledge about the process. This trial methodology involves trials in both a stable regime and degraded regimes caused by the wear or breakage of the tool. Second, it is necessary to define and configure a data acquisition system that allows us to record the trials with an adequate sampling frequency.

After the trials, we aim to identify different behaviours of the process depending on the material, the drill-bit diameter and the appereance of wear on the tool. More specifically, the aim is to gather information on the relation between the progress of the tool (the manipulated variable) and the power consumed in the head (the controlled variable) at different points of the operation. The results of these analyses provide a starting point for the future design and development of control strategies for the drilling process.

Achievements

Amongst the achievements of the project, we can highlight the following:

- Design of a test bench: this includes sandwich parts for detecting heterogeneity (stainless steel, casting, and aluminium) and parts for detecting the wear of the tool (stainless steal and casting).

- Diseño e implantación de un sistema de adquisición que permite almacenar la potencia en el cabezal de la batería de ensayos a una frecuencia de adquisición de 200 muestras/s.

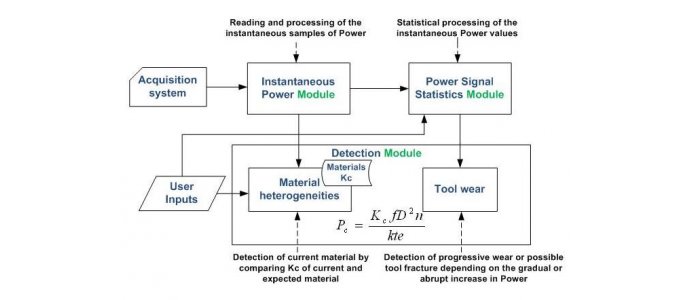

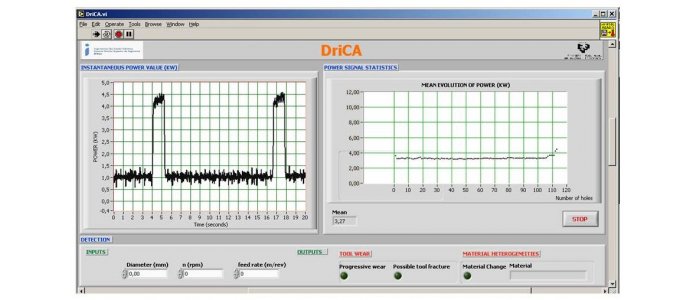

- Design and development of the Drilling Process Computer Assistant DriCA with LabViewTM. It involves 3 modules: (1) An Instant power module, which provides information about the current value of the power; (2) A statistical module that can analyse the devolpment of the power signal throughout multiple holes; (3) A detection module, which provides information about the occurrence of tool wear and the hetereogeneities of the part.

Acknowledgements

This work has been subcontracted by the company IDEKO, S. COOP. through the Euskoiker Foundation.

Software

DriCA, developed with LabviewTM.