The Project

Application of intelligent control techniques in wire electrical discharge machining. Aplicación de técnicas de control inteligente en el proceso de electroerosión por hilo (UPV05/114)

- Lead Researchers: Itziar Cabanes Axpe - (01/12/2005 - 30/11/2007)

- Research Area: Intelligent manufacturing and industry

- Funding Body: University of the Basque Country

Objectives

Based on results from previous projects (Empirical modelling of Wire electrical discharge machining to optimise the discharge quality, and Analysis and Diagnosis of discharge quality in wire electrical discharge machining), which show that, although the basic features of the degraded behaviours are the same in both thicknesses analysed, the thresholds met by virtual measures differ. Thus, we propose the definition of one structure that can automatically adapt parameters in a given range of thicknesses, with the aim of avoiding the need to establish a set of heuristic rules for each thickness and also having to repeat the analysis for the target thickness.

Further, we aim to estimate the degree of influence of each of the degraded behaviours in the degrading process. This estimation allows us to implement future strategies depending on the type of degraded situation.

Both objectives (to detect cutting regimes foreseeing the wire breakage with intermediate thickness compared to the those previously studied, and to estimate the degree of influence of each of the degraded behaviours in the degrading process) must be achieved by one structure.

Achievements

Amongst the achievements of this project, we can highlight the following:

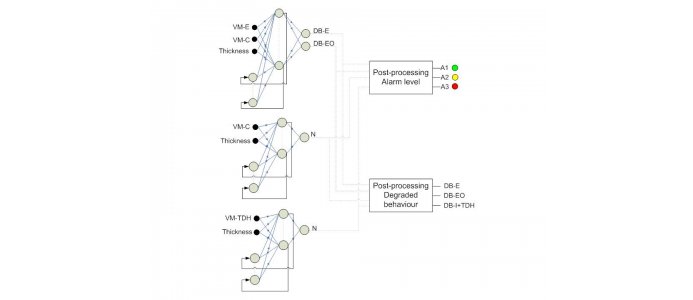

- Results of a comparative study of different network configurations based on static (PM) and recurrent (Elman) architectures. This study shows that the Elman architecture is the most adequate to meet the proposed objectives.

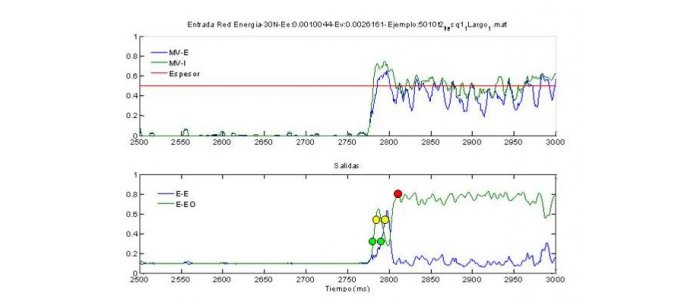

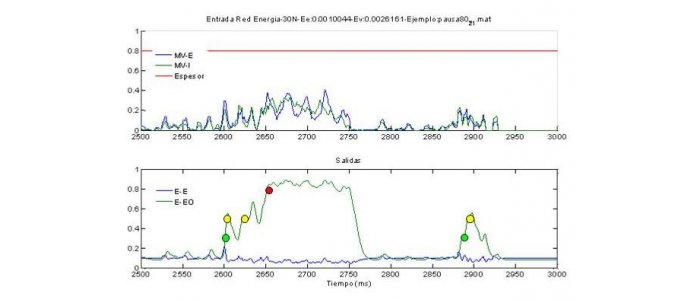

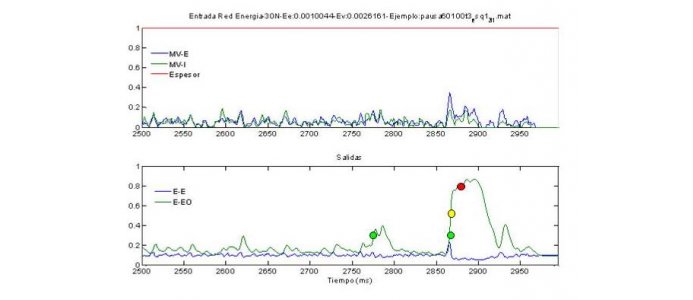

- Obtaining a parallel configuration of neural networks based on the recurrent architecture (Elman), that can detect different types of degraded behaviour in a range of thickness between 50 and 100 mm. Moreover, such a configuration can estimate the degree of influence of the different types of degraded behaviours.

Acknowledgements

This work has been funded by the University of the Basque Country within the project UPV05/114: Application of intelligent control techniques in wire electrical discharge machining.

Software

In order to carry out the example preparation, training and validation phases, we developed different applications using the neural network tool MatLabTM, Samplechopkper, Triner and NetSim.