The Project

Empirical modelling of wire electrical discharge machining to optimise the quality of discharge. Modelado empírico del proceso de Electroerosión por Hilo para la Optimización de la Calidad de las descargas (OD02UN45)

- Lead Researchers: Marga Marcos - (17/10/2003 - 06/10/2005)

- Research Area: Intelligent manufacturing and industry

- Funding Body: Basque Country Government (SAIOTEK) and ONA-ELECTROEROSIÓN

Objectives

The main aim of this project is to obtain empirical modelling of wire electrical discharge machining (WEDM) by implementing a series of experimental tests for different cutting regimes and for different workpiece thicknesses. For this, we define an acquisition and dignosis system performed on an industrial WEDM. The aim of such a system is to analyse a wide range of tests in order to detect a set of key variables that allow us to foresee the wire breakage and instability of the process.

Achievements

Amongst the main achievements of the projects, we can point out the following:

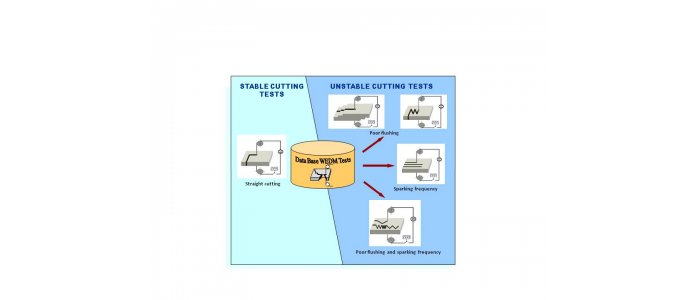

- Design of a set of tests: designing a set of tests that can differenciate between situations of stable cutting regimes and degrading cutting regimes for stainless steel workpieces of between 50 and 100 mm in thickness.

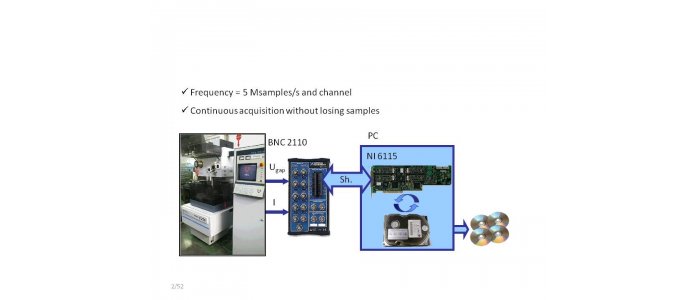

- Designing and implementing an acquisition system that allows us to gather, in real time, the stable and degrading cutiing regimes with an acquisition frequency of 5 Msamples/s and signal.

- Identifying the key variables of the process that allow us to detect degraded cutting regimes. Such variables are: I Discharge energy, Peak current Ip, and ionization time td.

Acknowledgements

This work has been funded by the Industry department of the Basque Government and ONA Electroerosión, S.A., within the project offer-demand OD02UN45 Empirical modelling of wire electrical discharge machining to optimise the quality of discharge.

Software

Acquisition system, developed with LabviewTM.