The Project

Analysis and diagnosis of the quality of discharge in the electrical discharge machining process. Análisis y diagnóstico de la calidad de la descarga en el proceso de electroerosión por hilo (1/UPV00146.363-T-15319/2003)

- Lead Researchers: Itziar Cabanes Axpe - (01/12/2005 - 30/11/2007)

- Research Area: Intelligent manufacturing and industry

- Funding Body: University of the Basque Country

Objectives

The main aim of this project is to determine the quality of discharge in wire electrical discharge machining from a database created with a comprehensive set of experiences in both stable and degraded regimes.

The project focuses on the study and description of the quality of discharge so that in the future, the control system of the machine is capable of detecting the tendency of the process early and can correct the malfunctioning in advance.

Thus, based on previous results (Project “Empirical modelling of the Wire electrical discharge machining to optimise the discharge quality”) we aim to characterise the degrading behaviours of the process. Once we have validated such characterisation, we will design and develop the prototype of real-time diagnosis.

Achievements

Amongst the achievements of this project, we can highlight the following:

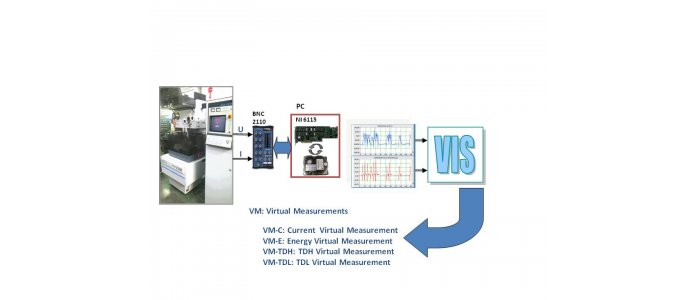

- Development of the Virtual sensor concept, whose main advantage is that it is based on software processing.

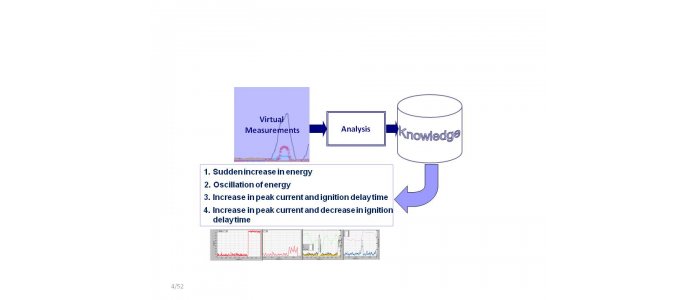

- Intensification of four types of degrading behaviour: increase of the peak intensity and ionization time (TR-I+TDH), abrupt increase of the energy (TR-E), successive peaks of energy (TR-EO), and increase of the peak intensity and decrease in ionization time (TR-I+TDL).

- Definition of an efficiency ratio RE that involves the influence of false negatives as well as false positives. The results have been satisfactory, and the global mean Efficiency Ratio is approximately 87%.

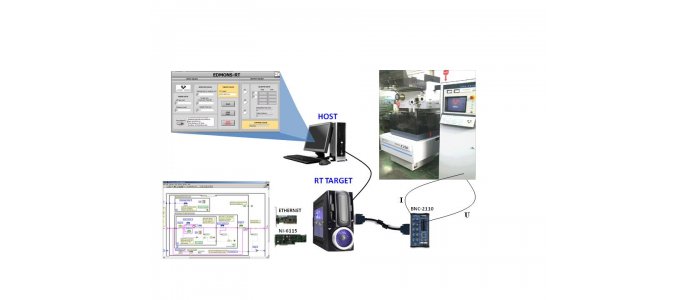

- Design and development of the real-time prototype EDMONS-RT using the real-time module LabViewTM-RT. This prototype took less that 9 ms to diagnose the wire breakage. Thus, given a timeframe specification with a 20% security margin at the worse case (12ms), we assure a diagnosis with at least 3ms flexibility, which could be used in the future to react and therefore avoid the wire breakage.

Acknowledgements

This work has been funded by the University of the Basque Country under the project named 1/UPV00146.363-T-15319/: Analysis and Diagnosis of the Discharge quality in wire electrical discharge machining.

Software

EDMONS, developed with LabviewTM.

Prototype of real-time EDMONS-RT with the real-time module LabViewTM-RT.