Research Areas

Intelligent manufacturing and industry

About the research area

The Virtual Sensorization research group (VISENS) started working on Intelligent Manufacturing and Industry around 2002 in collaboration with the High performance manufacturing research group at the Faculty of Engineering in Bilbao.

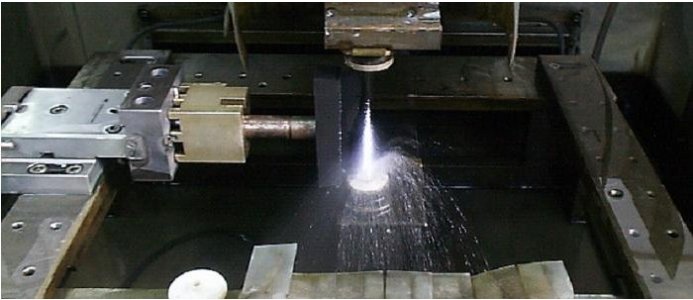

VISENS unifies the knowledge of the manufacturing process (in particular, electrical discharge machining, grinding, drilling, and laser metal deposition) using knowledge related to Systems and Automation Engineering (control, instrumentation, real-time IT systems, artificial intelligence, etc.). The work in this area focuses mainly on the proposal of new approaches for the application of artificial neural networks, as well as unsupervised classification techniques and optimisation algorithms, mainly aimed at the Virtual Sensing of systems governed by implicit relationships. Thus, intelligent diagnostic tools have been developed for the wear of grinding wheels, degradation of the WEDM process, and the modelling of different variables (for example, roughness, specific cutting energy, etc.), all using intelligent techniques.

In addition, VISENS has also tackled the design and development of virtual sensors in the Oil and Gas Industry 4.0 (in collaboration with Tecnalia and Petronor), providing new methods based on machine learning techniques for estimating the quality of petroleum products.